Reverse

Osmosis

Invest in the Oasis RO plant for premium vehicle wash results withon-site, pure rinse water production.

High-Quality Reverse Osmosis Systems

The demand for demineralised water produced by reverse osmosis is on the rise across various industries. This process employs membrane technology to effectively eliminate minerals from feed water, resulting in a superior quality permeate. ByWater Services specialises in providing turnkey Reverse Osmosis (RO) systems for water purification, complete with pre-treatment equipment and water storage.

Our offerings start from 240 litres per hour and can be tailored to any specific requirements. We offer a comprehensive range of RO systems capable of treating diverse feed waters. Our services encompass design, manufacturing, installation, and maintenance of both new and existing plants.

Enhance Vehicle Wash Quality with Oasis RO

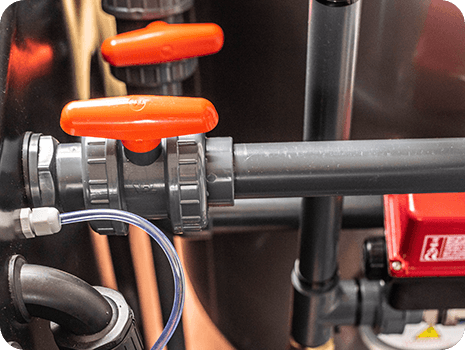

For exceptional results in your vehicle wash operations, consider investing in an Oasis RO plant. The Oasis RO system is designed to generate pure rinse water on-site, on-demand, and ready for use in the vehicle wash process. This treated water serves as the final rinse, delivering exceptional wash quality.

The Reverse Osmosis process has the capability to purify ordinary tap water, typically reducing the Total Dissolved Solids (TDS) or ‘spotting’ content of mains water by an impressive 99%. Our system is fully automatic and user-friendly, ensuring hassle-free operation. The Oasis RO is available as a turnkey solution with minimal on-site installation requirements, making it a cost-effective and efficient choice for increasing your vehicle wash water quality.

Benefits:

Exceptional Water Purity

Reduced Total Dissolved Solids (TDS)

Fully Automatic Operation

User-Friendly

Turnkey Solution

GET IN TOUCH